Introduction

Regarding downhole drilling, tools can make or break a project. Understanding downhole tools is crucial for successful drilling operations. Each plays a vital role in the process, from measurement and logging tools to production tools. This is where Teamwhole comes in as a leader in downhole technology, offering the best oil & gas drilling tools for efficient and effective drilling.

Understanding Downhole Tools

Downhole tools are specialized equipment in the oil and gas industry for various drilling operations. They are designed to withstand extreme conditions and provide accurate measurements and data for the successful completion of drilling projects.

Downhole tools play a crucial role in the success of drilling operations, as they are essential for gathering accurate data on well conditions and formations. Choosing the right tool is important because it directly impacts the efficiency and safety of drilling projects. An incorrect or subpar tool can lead to costly delays, inaccurate measurements, and potential hazards for workers and equipment. Therefore, oil and gas companies must invest in high-quality downhole tools specifically designed for the unique challenges of drilling operations.

Importance of Choosing the Right Tool

Selecting the right downhole tool is critical for a successful drilling operation. Here's why Teamwhole should be your partner:

- Engineered for Excellence: We utilize cutting-edge technology and innovative design to create a comprehensive range of downhole tools built to excel in diverse drilling environments.

- Maximized Efficiency, Minimized Downtime: Each meticulously crafted tool prioritizes efficiency, reducing downtime and keeping your project on schedule.

- Cost-Effective Solutions: Our focus on maximizing efficiency translates to significant client cost savings.

Teamwhole empowers you to achieve optimal drilling results. Contact us today to discuss your needs and explore how our downhole tools can elevate your next project.

Teamwhole: A Leader in Downhole Technology

As one of the leading downhole tools companies, Teamwhole offers a wide range of high-quality downhole drilling tools designed to meet the specific needs of different drilling projects. With a focus on innovation and reliability, Teamwhole is an industry leader in providing top-of-the-line downhole technology solutions.

In addition to offering a wide range of high-quality downhole drilling tools, Teamwhole also provides comprehensive technical support and training to ensure that clients can maximize the effectiveness of their equipment. With a team of experienced engineers and technicians, Teamwhole is dedicated to delivering exceptional customer service and ongoing assistance throughout the lifespan of their products. This commitment to customer satisfaction sets Teamwhole apart as a trusted partner in the oil and gas industry.

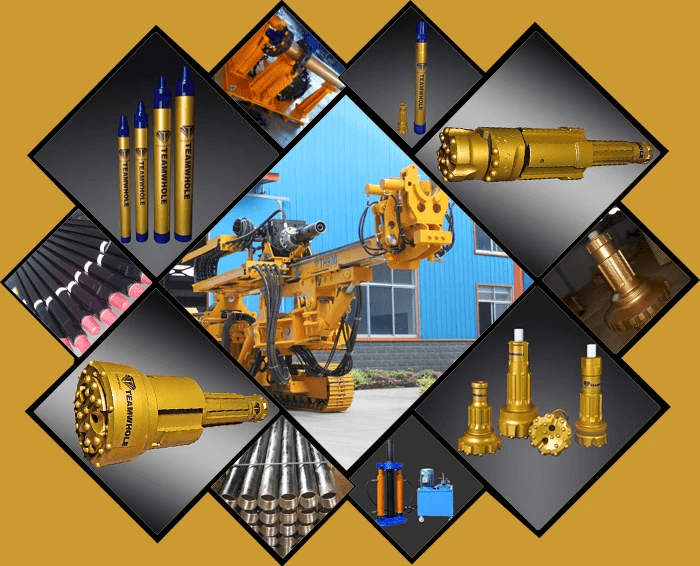

Types of Downhole Tools

Three main types of downhole tools play a crucial role in the oil and gas industry. First, we have the downhole drilling tools essential for the actual drilling process. These tools include drill bits, reamers, and stabilizers, all designed to help create boreholes in the earth's surface for oil and gas extraction.

Drilling Tools

Downhole drilling tools are at the heart of any drilling operation. They come in various shapes and sizes to accommodate geological formations and drilling requirements. From PDC bits to tricone bits, these tools are engineered to withstand extreme conditions deep within the earth's crust.

Downhole drilling tools are essential for successful drilling operations but are only part of the equation. Measurement and logging tools are crucial in providing real-time data on the drilling process. These tools help operators make informed decisions about good placement, formation evaluation, and overall drilling performance. With advanced technology, measurement and logging tools have become more accurate and reliable, allowing for greater efficiency and cost savings in drilling operations.

Measurement and Logging Tools

Measurement and logging tools are essential for assessing the wellbore's conditions and potential productivity. Engineers can make informed decisions about the drilling process by gathering data on rock formations, pressure levels, and temperature. This critical information allows adjustments to be made in real-time, ensuring the well is drilled efficiently and safely.

Production Tools

Production tools optimize oil and gas recovery once a well has been drilled and completed. These tools include artificial lift systems, downhole pumps, packers, and other equipment designed to enhance production rates while minimizing downtime. Operators must carefully consider the specific reservoir conditions, such as pressure and temperature, when selecting the most suitable production tools. Additionally, the compatibility of these tools with existing infrastructure and the potential for future expansion should also be considered to ensure long-term success in maximizing oil and gas recovery.

Factors to Consider

When it comes to downhole tools, one of the most crucial factors to consider is the tool material and quality. The materials used in their construction directly impact the tools' durability and performance. High-quality alloy steel, advanced heat treatment, and precision engineering are essential for ensuring the longevity and effectiveness of downhole drilling tools.

Tool Material and Quality

The choice of material for downhole tools is paramount in ensuring their reliability and longevity. High-quality alloy steel is a must-have for withstanding the extreme conditions encountered during drilling operations. Teamwhole's downhole tools are made from premium alloy steel, renowned for its exceptional strength and durability, ensuring optimal performance in demanding drilling environments.

The design and construction of downhole tools play a significant role in their performance and longevity. Teamwhole's tools are meticulously engineered to be compatible with a wide range of drilling equipment, ensuring seamless integration and efficient operation. This compatibility enhances the overall drilling process and reduces downtime and maintenance costs, making Teamwhole's tools a reliable choice for any drilling operation.

Compatibility with Drilling Equipment

Another critical factor to consider when selecting downhole tools is their compatibility with drilling equipment. The seamless integration of these tools with the existing drilling setup is essential for achieving efficient and successful operations. Teamwhole's range of downhole tools is designed to seamlessly integrate with various types of drilling equipment, offering versatility and ease of use.

Furthermore, it is important to consider the environmental conditions in which the drilling equipment and downhole tools will be operating. Teamwhole's range of downhole tools is designed to withstand various environmental challenges, including high temperatures, high pressures, and corrosive fluids. This ensures the tools can perform reliably in diverse drilling environments, minimizing downtime and maximizing operational efficiency.

Environmental Conditions

The environmental conditions in which downhole drilling takes place can vary significantly, from high-temperature environments to abrasive formations. Choosing downhole tools that can withstand these harsh conditions without compromising performance or safety is essential. Teamwhole's advanced heat-treatment technology provides wear protection, ensuring their tools can withstand extreme environmental conditions while maintaining peak performance.

When selecting downhole tools, it's also important to consider the specific geological conditions of the drilling site. Different formations, such as soft shale or hard limestone, require different tool designs and materials to ensure optimal performance. Teamwhole's expertise in understanding the geological challenges of drilling sites allows them to tailor their tools to meet these specific needs, providing superior reliability and efficiency in various drilling environments.

Choosing the Best Downhole Tool

When researching leading companies for downhole tools, it is crucial to look for a track record of innovation and reliability. Companies with a deep understanding of downhole technology and a commitment to continuous improvement often develop the best oil and gas drilling tools.

Researching Leading Companies

Look for downhole tools companies with a solid reputation in the industry, known for their expertise in designing and manufacturing high-quality downhole drilling tools. Seek customer reviews and testimonials to gauge their performance and reliability in the field.

After identifying downhole tool companies with a strong industry reputation, it's important to delve deeper into their track record of delivering high-quality products. Look for successful projects or case studies that showcase the company's ability to meet and exceed customer expectations. This will provide valuable insight into their drilling tools' real-world performance and reliability, helping you make an informed decision when evaluating potential partners.

Evaluating Tool Performance

Downhole drilling conditions can be harsh, so choosing the right tools is crucial for success. Here are three key factors to consider when evaluating downhole tooling performance:

- Reliability and Performance: Look for tools with a proven track record of delivering consistent results, even in challenging downhole environments. Prioritize tools that have been rigorously tested to ensure they can withstand the demands of your specific drilling operation.

- Maintainability and Serviceability: Minimize downtime and keep operating costs low by selecting easy tools to disassemble, repair, and reassemble. Readily available spare parts are also essential. This focus on maintainability will contribute to the tool's overall cost-effectiveness in the long run.

- Compatibility: Ensure the downhole tool seamlessly integrates with your existing drilling equipment. A tool that complements your existing systems can significantly improve overall efficiency and productivity, ultimately contributing to cost-effective operations.

By carefully considering these factors, you can select downhole tooling that optimizes performance, minimizes downtime, and keeps your drilling operation running smoothly.

Cost-Effectiveness of Tools

While it's important to prioritize quality, cost-effectiveness is also a key consideration when choosing the best downhole tool. Evaluate the total cost of ownership, including maintenance and replacement expenses, to ensure you get the best value for your investment.

Remember that investing in high-quality downhole tools is essential for efficient drilling operations. By carefully researching leading companies, evaluating tool performance, and considering cost-effectiveness, you can make an informed decision to benefit your drilling operations in the long run.

Teamwhole Downhole Tools

Range of DTH Bit Sizes

Having the right bit size for downhole drilling is crucial for efficiency and precision. Teamwhole offers a wide range of Down-The-Hole (DTH) bit sizes to suit various drilling needs, ensuring you have the perfect tool for the job every time.

Quality Alloy Steel Material

Teamwhole takes pride in using only the highest-quality alloy steel for its downhole tools. This ensures durability, strength, and reliability in even the most demanding drilling conditions, making it one of the best oil and gas drilling tools companies in the industry.

Advanced Heat-Treatment for Wear Protection

One key factor that sets Teamwhole apart is its advanced heat-treatment process for wear protection. This ensures that its downhole tools can withstand extreme wear and tear, prolonging their lifespan and maximizing performance in downhole drilling.

Now that we've covered Teamwhole's impressive range of DTH bit sizes, high-quality alloy steel material, and advanced heat-treatment for wear protection, it's clear why they stand out as leaders in downhole technology and tooling solutions.

Advantages of Teamwhole Tools

Teamwhole stands out in the downhole drilling industry for its versatile and innovative tools.

Here's why Teamwhole should be your top choice for downhole tooling:

- Adaptable to Various Conditions: Teamwhole offers a range of bit head face designs, including convex, flat, and concave. This allows their tools to easily tackle various drilling conditions and rock formations.

- Ensures Efficient Operations: Teamwhole promotes efficient drilling regardless of the environment by providing the right tool for the job.

- Commitment to Versatility: Teamwhole prioritizes versatility in its downhole tool design, making it a perfect choice for any drilling project.

Teamwhole's downhole drilling tools are valuable for any drilling operation because they focus on adaptability and efficiency.

Versatile Bit Head Face Designs

Teamwhole's downhole tools boast versatile bit head face designs catering to drilling requirements. Whether it's soft or hard formations, the various face designs ensure optimal performance and efficiency. The convex design allows for smooth penetration in softer formations, while the concave design provides stability and control in harder rock formations. This adaptability makes Teamwhole tools a reliable option for any drilling project.

Various Carbide Shapes for Different Rock Formations

To further enhance their versatility, Teamwhole offers various carbide shapes to tackle different rock formations easily. These tools can handle any drilling challenge, from chisel-shaped carbides for soft formations to spherical-shaped carbides for hard formations. This comprehensive approach to tool design sets Teamwhole apart from other downhole tool companies in the industry.

Extreme Protection Against Wear and Fatigue

Teamwhole's commitment to quality extends to providing extreme protection against wear and fatigue. Utilizing advanced heat-treatment processes and high-quality alloy steel material, their tools are built to withstand the harshest drilling conditions without compromising performance. This durability ensures longevity and reliability, making them the best oil & gas drilling tools available.

With their versatile bit head face designs, various carbide shapes for different rock formations, and extreme protection against wear and fatigue, Teamwhole's downhole tools are unmatched in the industry. When choosing the best downhole tooling for efficient drilling operations, Teamwhole stands out as the leader in downhole technology.

Make the Right Choice for Downhole Tools

When it comes to downhole drilling, choosing the right tools is crucial for success. Investing in quality downhole tools is essential for efficient drilling operations, and Teamwhole stands out as a leader in downhole technology. With high-quality downhole drilling tools and advanced technology, Teamwhole provides the best oil & gas drilling tools for any project.

Selecting the best downhole tooling is a decision that can greatly impact the outcome of drilling operations. It's important to carefully consider factors such as tool material, compatibility with drilling equipment, and environmental conditions. By choosing Teamwhole's top-of-the-line downhole tools, you can ensure that you are making the right choice for your drilling needs.

Investing in Quality Tools for Efficient Drilling

Investing in quality downhole tools is crucial for achieving efficient and successful drilling operations. Teamwhole offers a wide range of high-quality downhole tools designed to withstand the toughest drilling conditions. By investing in Teamwhole's advanced technology and expertise, you can optimize your drilling efficiency and productivity.

Why Teamwhole Stands Out in Downhole Technology

Teamwhole stands out among other downhole tools companies due to its commitment to providing the best oil & gas drilling tools on the market. With a focus on innovation and quality, Teamwhole offers versatile bit head face designs, various carbide shapes for different rock formations, and extreme protection against wear and fatigue. When it comes to downhole technology, Teamwhole sets the standard for excellence.